About us

Our history

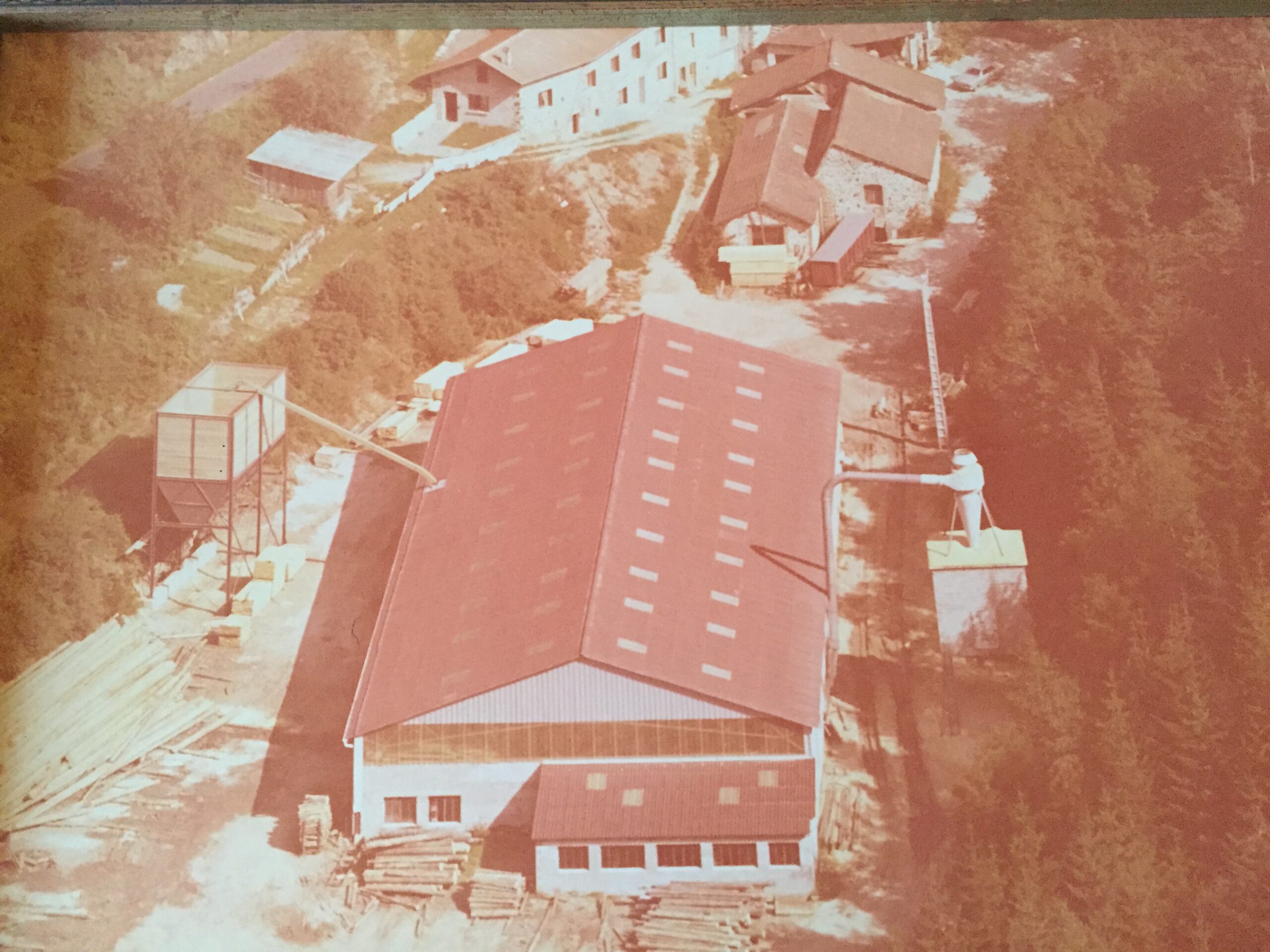

1916

Creation of Scierie Moulin : Founded in 1916, Scierie Moulin marked the beginning of our journey in the wood industry. From the outset, the company distinguished itself by its expertise and dedication to delivering quality products.

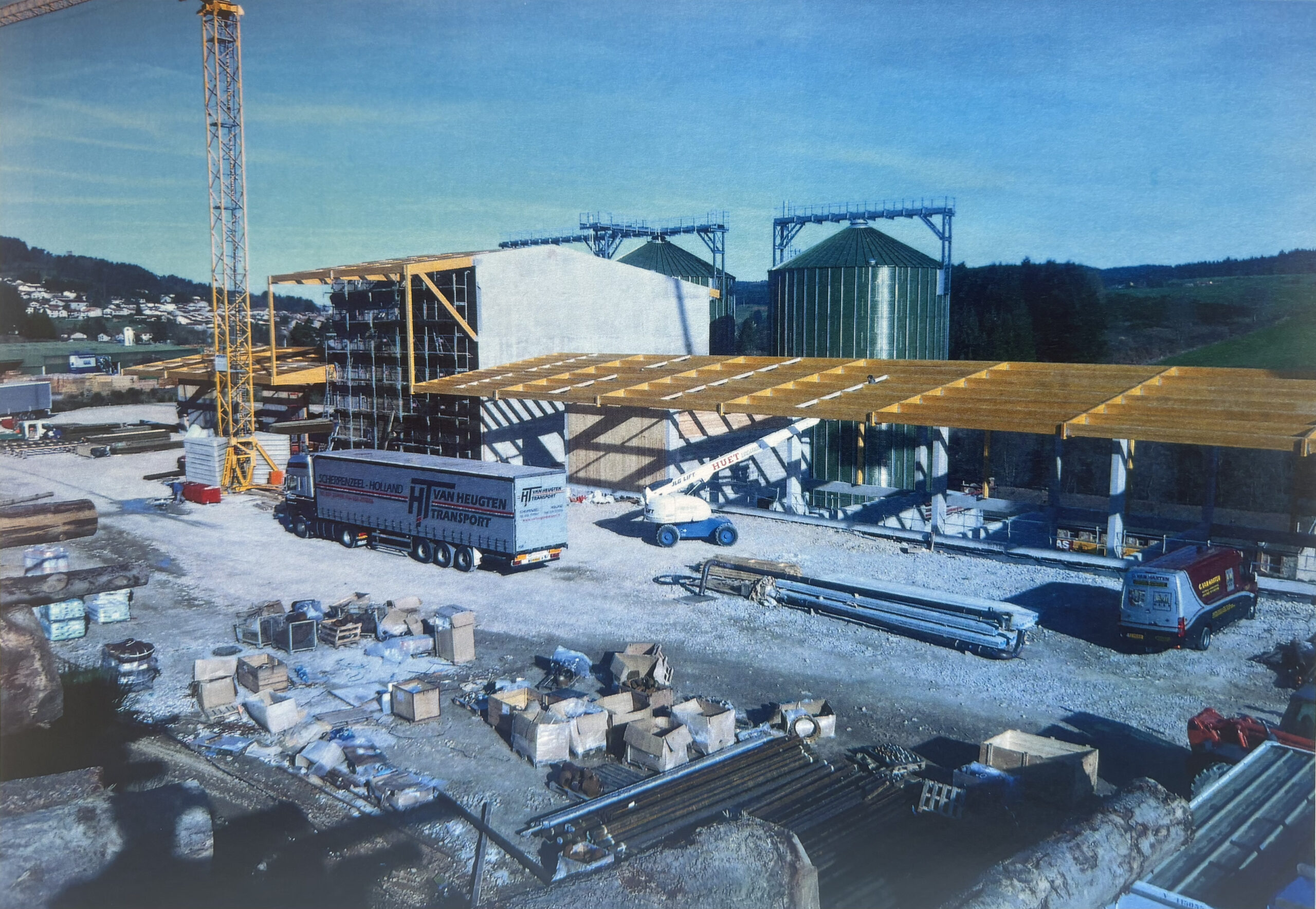

1992

Relocation to the Dunières Site : In 1992, the sawmill relocated to a 20-hectare site in Dunières, marking a turning point in our production capacity and ambition to grow while preserving the environment.

2007

Creation of Moulin Bois Énergie : With the establishment of Moulin Bois Énergie, we launched a new era of innovation by introducing wood pellets and cogeneration, demonstrating our commitment to renewable energy and sustainable resource management.

2012

Opening of the New Log Yard : The year 2012 saw the opening of our log yard, optimizing our resource management to ensure environmentally friendly production.

2013

Acquisition of FBI : In 2013, we acquired FBI, strengthening our expertise and expanding our range of services to meet the evolving needs of our clients.

2016

Launch of the Planing Mill : As pioneers in automation, we introduced the Planing Mill in 2016, revolutionizing our production processes to offer greater precision and quality in our finished products.

2020

New Sawing Line : In 2020, we implemented a new sawing line, increasing our production capacity while ensuring efficient and responsible use of natural resources.

2022

Modernization of the Treatment Station : Our treatment station was modernized and expanded in 2022, with the installation of a state-of-the-art autoclave to ensure the durability and resilience of our products.

2023

Nouvelles installations : En 2023, nous avons ajouté un bicoupe et un classeur, ainsi qu’un traitement avancé, optimisant notre production de bois de haute qualité.

2023

New facilities: In 2023, we added a bicutter and grader, as well as advanced treatment, optimising our production of high-quality timber.

2023

New facilities: In 2023, we added a bicutter and grader, as well as advanced treatment, optimising our production of high-quality timber.

2023

New facilities: In 2023, we added a bicutter and grader, as well as advanced treatment, optimising our production of high-quality timber.

2023

New facilities: In 2023, we added a bicutter and grader, as well as advanced treatment, optimising our production of high-quality timber.

2024

The arrival of a new machine: We have installed a rounding machine to improve the preparation of our logs, making sawing easier and optimising our products.

Commitment to Sustainable Development

At Moulinvest, sustainable development is more than a concept; it is a fundamental pillar of our company philosophy. We take pride in using every part of the forest resource efficiently and responsibly.

The Moulinvest Team: Expertise and know-how

Our people are our strength, because we believe that human expertise is at the heart of our success. Our team shares a passion for wood and innovation, which enables us to stay at the cutting edge of technology and market trends.

– Continuous innovation : Our engineers and technicians work to develop modern solutions that meet the changing needs of our customers and partners.

– Training and Development : We invest in the ongoing training of our staff to guarantee a constant level of excellence and the ability to respond to all our customers’ needs.

Why Choose Moulinvest?

Moulinvest is synonymous with quality, innovation, and responsibility. Here’s why our clients trust us:

Replanting

With a constant focus on sustainability, we engage in reforestation to ensure a greener future.

Cut

Our environmentally-friendly cutting methods ensure optimum use of forest resources.

Impregnation

Our innovative impregnation process ensures the longevity and robustness of our wood products.

Transport

We offer efficient transport solutions, allowing us to deliver our products on time while reducing environmental impact.